Cultivating

Progress

VISION

Our vision is to be a leading enabler

of the biosolutions urgently needed

to restore planetary health

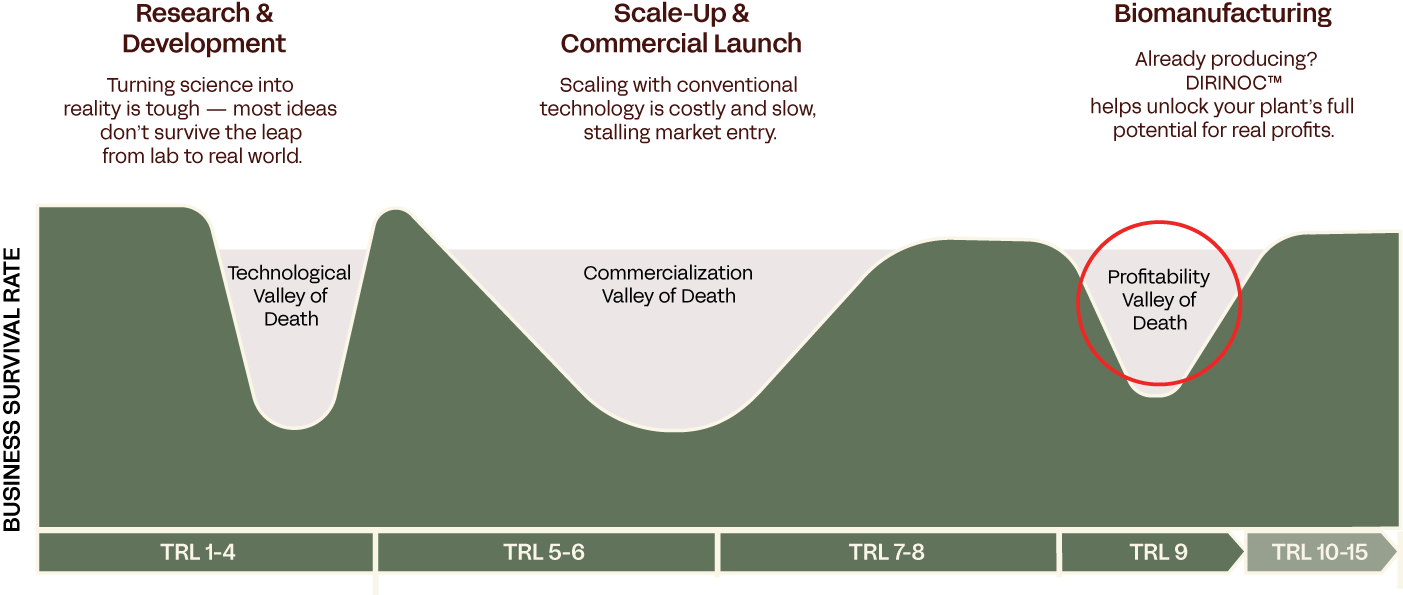

STATUS QUO

Too many fermentation businesses fail

Start your journey - choose a track

With FlexCell® technology, you can rapidly validate your microbial innovations, reduce development costs, and pave the way for safe, efficient deployment at industrial scale.

If you need robust strain-to-starter-culture development, or quality certified inoculum for biomanufacturing, this is for you.

DIFFERENCE

DIRINOC™

Our Direct Inoculum technology radically

improves profitability, flexibility and efficiency.

With our seed train services we enable companies to obtain a readily available concentrated

starter culture that seeds the commercial scale bioreactor and yields considerable savings.

CORPORATES AND CDMOs

ORIP

Organism Robustness Induction Program

This is the development program, starting with the transfer of the strain,

and ending with an orderable, stable starter culture.

-

Metabolic pathway mapping using a proprietary AI model suggesting best strategies for production of a stable, storable, concentrated starter culture

-

Wet trials in the lab for optimal media formulation, propagation conditions, concentration- and packaging strategy

-

Validation run using our FlexCell® production platform.

Quality certification and packaging logistics determined. -

Order your starter culture whenever you need it!

CORPORATES AND CDMOs

DIRINOC™

DIRINOC™ is a ready-to-use starter culture, developed from the client’s own strain after going through the ORIP program.

It’s available on demand and ready for direct use in fermentation.

CORPORATES AND CDMOs

We are agnostic to which microbe...

We can handle almost any species, wild type or genetically modified organisms, unlocking microbial biodiversity in biomanufacturing.

FlexCell® —

the breakthrough tech that makes progress possible

STARTUPS & SCALE-UPS

Our proprietary FlexCell® technology gives food and biotech companies of any size a faster and dramatically more affordable way to validate the commercial potential of their microorganism.

STARTUPS & SCALE-UPS

Step 1 / Customize your FlexVessel bioreactor

-

Works for a wide array of microorganisms, including yeast, filamentous fungi, bacteria and algae

No risk of cross-contamination

-

Unlimited and immediate configurations for ports and probes, available across bioreactors ranging from 10 L to 400 L, ensuring adaptability for any food- or biotech-grade application

-

No need for time-consuming CIP (Clean-in-Place) and SIP (Sterilize-in-Place). Run unlimited fermentations side-by-side

-

Compatible with stock or proprietary propagation media

STARTUPS & SCALE-UPS

Step 2 / Define your process parameters and data collection

-

— Substrate

— Temperature

— Oxygen availability

— Substrate feed

— pH, and more

-

— Density & pH

— Optical density

— Dissolved oxygen

— Gas mass-flow (CO2 etc.)

-

— Fingerprinting

— Titer

— Target molecule quantification

— qPCR

— Viability

— Productivity

— Biomass Yield

STARTUPS & SCALE-UPS

Step 3 / Select your quality parameters, downstream processing and product harvest

-

We collaborate with you to establish the most relevant quality parameters, customizing them to fit your process

-

We offer non-intrusive biomass concentration and harvest solutions

-

Our capabilities ensure you meet all relevant organic, food safety, GMO and ISO standards, certifications and requirements

-

If needed, strains can be cryogenically stored, ready for deployment at short notice

Your needs, Our priority

Tell us what you’re looking for — we’ll do the rest.

Fast, simple, and effective.

First there was a company that made yeast...

Swan Neck Bio™ is a spin-out from White Labs - a global leader in fermentation since 1995.

White Labs’ pioneering FlexCell technology revolutionized the brewing industry by enabling yeast to be grown and packaged in the same vessel.

At Swan Neck Bio, we’re applying this single-use bioreactor technology to produce ready-to-use seed cultures of any microbe for biomanufacturing applications around the world.

Track record